- About us

- Solutions

-

Concrete and Mortar

-

Exterior Waterproofing

Exterior Waterproofing

Other Products

Professional Sealants

Professional Sealants

Roof Waterproofing

Roof Waterproofing

New Roof

Roof Rehabilitation

Substructure Waterproofing

Substructure Waterproofing

Tiling and Grouting

Tiling and Grouting

Cement based Tile Adhesives

Cementitious Grouts

Epoxy Tile Grouts

PU Modified Hybrid Epoxy

Water Tanks and Other Areas

Water Tanks and Other Areas

Wet Areas

- products

Cementitious Coatings

Cementitious Coatings

Cementitious Grouts

Cementitious Grouts

Cementitious Tile Adhesives

Cementitious Tile Adhesives

Epoxy Coatings

Epoxy Coatings

Epoxy Tile Grouts

Epoxy Tile Grouts

Exterior Acrylic Coatings

Integral and Latex Polymers

Integral and Latex Polymers

Professional Sealants

Professional Sealants

Protective Coatings

Protective Coatings

PU Coatings

PU Coatings

PU Modified Hybrid Epoxy Adhesive

PU Modified Hybrid Epoxy Adhesive

Roof Acrylic Coatings

Roof Acrylic Coatings

- downloads

- warranty

- Media

- contact us

-

Home

- Water Tanks and Other Areas

Find our latest products & Unleash the Waterproofing Powerhouse for All Your Surfaces!

Water Tanks Waterproofing Solutions

Easy Application, Fast Results – Excellent Performance Guaranteed!

DISCOVER ASTRAL TRUBUILD

What is Water Tanks Waterproofing?

Water tank waterproofing is the process of creating a protective barrier inside or outside the tank so that water does not seep through the concrete, blockwork or plaster. This barrier helps to control problems like leakages, damp patches and efflorescence. It also supports better water tank maintenance over time.

With the right waterproofing solutions for water tanks, the coating works like a shield between stored water and the structure. Modern waterproofing treatment for tanks uses cementitious coatings, acrylic polymers and other waterproofing materials for tanks to give a durable, food grade layer suitable for potable water.

Why is Waterproofing for Water Tanks Important?

1. Structural Protection

Water tanks hold water for daily use, so any leakage or seepage quickly shows up as damp walls, peeling paint, rust stains and fungal growth around the structure. Timely water tank waterproofing helps to protect the tank from such damage. It also supports the overall hygiene of stored water. The importance of waterproofing grows in overhead and underground tanks that remain filled for long periods.

2. Hygiene and Maintenance

The benefits of tank waterproofing go beyond stopping visible leaks. A sound waterproofing treatment for tanks cuts down frequent repair work, keeps concrete stronger for longer and helps reduce contamination risk from external moisture. Regular waterproof tank maintenance combined with quality waterproofing solutions for water tanks also helps households and businesses manage water more efficiently throughout the year.

Types of Water Tanks Waterproofing Solutions

1. Common Materials Used

There are different types of waterproofing used for concrete and masonry water tanks. Each solution suits a specific site condition. The most common waterproofing materials for tanks include acrylic cementitious coatings, liquid membranes and food grade epoxy coatings. Among these, acrylic cementitious waterproofing tanks systems are popular for overhead and underground RCC tanks due to their balance of flexibility and durability.

2. Acrylic Cementitious Systems

Acrylic cementitious water tank waterproofing products combine liquid polymers with specially blended cement-based powders to form a tough, seamless membrane. This kind of waterproof liquid for water tank applications can be used on positive and negative sides, helping manage hydrostatic pressure from both inside and outside the tank. For many residential and commercial projects, a high-performance acrylic cementitious membrane is considered the best waterproofing solution for water tanks because it is non-toxic, can bridge small cracks and adheres well to concrete and masonry surfaces.

3. Other Waterproofing Technologies

Some projects may also use crystalline waterproofing materials for tanks that react with moisture in concrete to block pores or bitumen-based systems for non-potable water structures. In comparison, high-build, low-VOC acrylic cementitious systems give a more user-friendly option for water tank waterproofing solutions.

How to Waterproof a Water Tank?

Step 1: Surface preparation

The process of water tank waterproofing starts with thorough surface preparation. The substrate must be clean, structurally sound and free from oil, grease, loose particles or previous weak coatings. Spalled concrete is removed and repaired with suitable non-shrink grouts and polymer-modified mortars from the same system so that a stable base is ready for waterproofing treatment for tanks.

Next, all visible cracks up to around 5 mm are opened into a V-groove and filled with compatible crack filling compounds. Wider cracks are treated with polymer-modified mortars made with approved waterproofing materials for tanks to restore continuity. At wall–floor junctions, coving is created with polymer-modified mortar so that there are no sharp corners where stress can concentrate, which is a common source of waterproofing problems in tanks.

Step 2: Mixing and preparation of slurry

Before applying the waterproof liquid for water tank protection, the surface is brought to a saturated surface dry condition. This means it is damp but without standing water. For a two-component acrylic cementitious system, the recommended mixing ratio, such as 1:1.4 (liquid to powder by weight), is followed to obtain a smooth, lump-free slurry. The mix is left to stand for a few minutes so that entrapped air escapes and then used within the specified pot life.

Step 3: Application of coating

The mixture is then applied on the prepared surface with a brush or trowel at the recommended coverage rate. It is usually applied in a minimum of two coats to achieve the desired dry film thickness. The first coat is allowed to dry for about four to six hours at normal temperatures. After which, a second coat is applied in a cross direction. For better adhesion of protective screed or plaster in overhead and underground water tank waterproofing, coarse sand can be lightly broadcast on the wet second coat.

Step 4: Curing and testing

After application, proper curing is an important step in how to waterproof a water tank effectively. Air curing for a few hours is followed by moist curing with potable water spraying for about 24 hours. Then it needs further air curing for three to five days before screed or tiling work. For any ponding test or filling of the water tank, a minimum curing period of seven days is recommended so that the waterproofing tank coating develops full performance. Homeowners should opt for professional water tank waterproofing services for large or critical structures.

Benefits of Water Tank Waterproofing

1. Structural and Aesthetic Benefits

Good quality water tank waterproofing delivers clear structural and hygiene benefits. It helps control water seepage, reduces the chance of corrosion in embedded steel and protects surrounding finishes like plaster and paint from damp damage. These waterproofing benefits matter in both domestic and commercial buildings that rely on concrete water tanks for daily supply.

2. Long-term Performance

The long-term benefits of waterproofing include lower maintenance costs, fewer complaints of leakage and a longer life of the tank structure. A robust waterproofing treatment for tanks also supports clean water storage by reducing the risk of external contamination through cracks and pores. With the right product selection and regular waterproof tank maintenance, water tank protection becomes more reliable over many years.

Common Issues in Water Tank Waterproofing Solutions

1. Application-related Issues

Many common waterproofing issues in water tanks arise from poor surface preparation or shortcuts during application. If dust, oil or weak plaster remains on the surface, the waterproofing coating may debond or blister. Incorrect mixing ratios, insufficient thickness or even some missed areas near joints and pipe entries can also lead to problems with tank waterproofing.

2. Material and Design Issues

Other waterproofing problems in tanks show up over time in the form of hairline cracks, efflorescence and seepage marks. Thermal movement, structural cracks and negative hydrostatic pressure can stress the coating if an unsuitable material is chosen. Using the right types of waterproofing and following the full system, including crack treatment and coving, helps reduce such issues in water tank waterproofing systems.

How Long Does Water Tank Waterproofing Last?

1. Factors Affecting Lifespan

The lifespan of waterproofing in a water tank depends on product quality, surface preparation, application thickness and exposure conditions. Well-designed acrylic cementitious waterproofing tanks systems with good crack-bridging ability and adhesion can serve for many years under typical residential conditions. Independent test standards help validate the durability of waterproof coatings used in such applications.

2. Practical service life

In general, when the system is applied as per technical data, cured properly and protected with screed or plaster where needed, the durability of waterproof coatings is significantly higher than basic cement-sand coatings or patch repairs. Periodic inspection for visible damage, along with routine waterproof tank maintenance, can help users plan timely touch-ups or additional coats after several years of service.

How to Maintain Waterproofed Water Tanks?

1. Regular Inspection

Maintenance of waterproofed water tanks starts with simple visual inspections. Users can check for damp patches on external walls, peeling paint, efflorescence or any sign of leakage that may indicate early waterproofing problems in tanks. Inside the tank, filling and emptying cycles offer a good opportunity to look for cracks or damaged areas in the coating.

2. Cleaning and Minor Repairs

Basic waterproof tank maintenance also includes regular cleaning of the tank to control silt, algae and biofilm build-up. During such cleaning, harsh mechanical scraping of the coating is avoided so that the waterproofing layer remains intact. When any damage is noticed, it is better to repair the identified area with compatible waterproofing materials for tanks instead of temporary fixes that can affect the performance of the original system.

3. Professional support

For larger properties or critical applications like hospitals, professional inspections and structured water tank waterproofing services help keep maintenance of waterproofed water tanks on track. This approach supports better water tank protection and extends the practical lifespan of waterproofing systems.

Why Choose Astral Trubuild for Water Tank Waterproofing Solutions?

Advantages

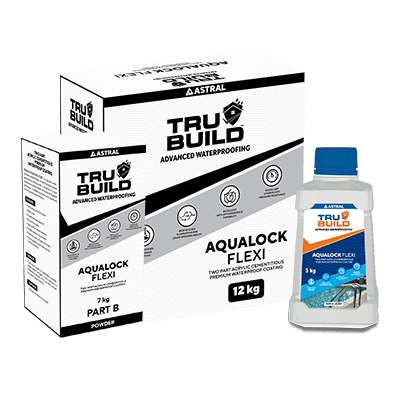

Astral Trubuild offers specialised water tank waterproofing products designed for concrete and masonry water retaining structures. Trubuild Aqualock Flexi is a premium acrylic cementitious waterproofing membrane that forms a flexible, seamless barrier with strong adhesion to concrete and masonry substrates. It is formulated as a two-component system with a liquid polymer and cementitious powder. It mixes into a smooth slurry suitable for brush or trowel application.

Safety and Performance

For water tank waterproofing solutions, Aqualock Flexi brings strong technical performance backed by recognised standards. It is CFTRI approved as food grade and non-toxic as per relevant standards. This makes it suitable for potable water tanks and reservoirs. The system offers high elongation, crack bridging and resistance to water penetration at pressure, giving dependable protection in overhead and underground water tank waterproofing jobs.

Support and System Approach

Astral Trubuild also supports professional waterproofing solutions with application guidance, product systems for crack repair and coving and technical data for specifiers and contractors. With a focus on quality, ease of application and long-term performance, Astral Trubuild helps homeowners and businesses choose the right waterproofing solutions for water tanks and maintain them with confidence.

FAQ

What is the best waterproofing solution for a water tank?

The best waterproofing solution for a water tank is usually a food grade, high performance acrylic cementitious coating that can bridge small cracks and resist hydrostatic pressure. Such water tank waterproofing products form a seamless, durable membrane suitable for potable water tank waterproofing solutions.

Can I waterproof my water tank myself?

DIY waterproofing for water tanks is possible for small domestic tanks if the user follows technical guidance carefully, including surface preparation, mixing and curing. For large or underground water tank waterproofing or where access is difficult, professional water tank waterproofing services are recommended for consistent quality and safety.

How can I prevent mould in my water tank?

Mould control in a water tank starts with regular cleaning, disinfection and removal of settled sludge. Effective water tank waterproofing with a non-toxic, food grade coating reduces seepage and damp pockets that support fungal growth. And proper waterproof tank maintenance keeps vents, covers and surroundings clean and dry.

Is waterproofing necessary for all water tanks?

Waterproofing is strongly recommended for concrete and masonry water tanks, both overhead and underground, because these materials are porous and prone to seepage and cracking. Proper water tank waterproofing and ongoing maintenance of waterproofed water tanks help extend structural life, reduce leakage complaints and support safer water storage in homes and commercial buildings.

Professional Sealants

Professional Sealants

Roof Waterproofing

Roof Waterproofing

Substructure Waterproofing

Substructure Waterproofing  Tiling and Grouting

Tiling and Grouting

Water Tanks and Other Areas

Water Tanks and Other Areas