| PROPERTIES | STANDARD | RESULTS |

|---|---|---|

| Mixing Ratio (By weight) | 1:2 (Part A liquid : Part B powder) | |

| Bulk Density of Powder | In House | 1.6 – 1.8 |

| Mixed Density Of Wet Mix, gm/ml | In House | 1.7 – 1.80 |

| Set to Touch Time at 25°C | In House | 45 min. |

| Water Absorption | In House | < 6 % |

| Adhesion to concrete after 7 Days | ASTM D 4541 | ≥ 1 mPa |

| Positive Hydrostatic Pressure | EN-12390 Part-8 | Pass |

| Tensile Strength – on casting | ASTM D 412 | upto 1MPA |

| Elongation at Break (%) | ASTM D 412 | Min. 60% |

| Crack Bridging | EN1062-7 | Upto 1 mm |

| WFT* ( 2 Coats ) | 1000 - 1200 micron | |

| DFT* ( 2 Coats ) | 800 - 1000 micron | |

| Food Grade Certification | CFTRI Certified | Pass |

- Concealed roofs, parking decks, bathroom, toilet, kitchen, balconies and planters

- Swimming pools, water tanks and reservoirs

- Concrete foundations, basements wall and lift pits

- Any other concrete, cement or masonry surface subject to damage from moisture

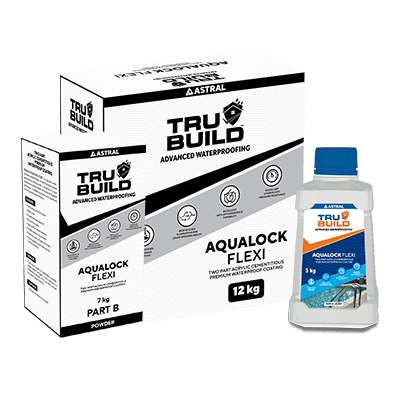

Trubuild Aqualock is a two-part acrylic cementitious waterproofing coating designed for concrete and masonry surfaces that face constant moisture and water pressure. This flexible waterproofing membrane coating helps create a seamless barrier in wet areas such as bathrooms, terraces, water tanks and swimming pools.

What is Trubuild Aqualock?

Trubuild Aqualock is an acrylic modified, cementitious, liquid-applied waterproofing membrane supplied as a ready-to-mix powder and liquid kit. When these two parts are mixed, they form a smooth slurry that bonds well with concrete and masonry to create a tough, flexible waterproofing layer. This cementitious waterproofing coating is suitable for both positive and negative water pressure conditions in residential as well as commercial projects.

Features of Trubuild waterproofing membrane coating

1. Strong bond with concrete and masonry

Trubuild Aqualock offers very good adhesion to concrete, plaster and masonry, which helps the waterproofing membrane stay intact over time.

2. Flexible waterproofing film for hairline cracks

The acrylic modified cementitious system forms a flexible cementitious coating that can bridge minor hairline cracks and small movements in the substrate.

3. Safe, low‑VOC and non‑toxic formulation

Aqualock cementitious waterproofing coating is non‑toxic and free from volatile organic compounds, so it is suitable for internal areas and water retaining structures.

4. Brush or trowel friendly application

The mixed slurry has a workable consistency and can be applied using a brush or trowel without any water dilution.

5. High resistance to water pressure

The waterproofing membrane coating can withstand positive hydrostatic pressure up to about 5 bar and negative pressure up to about 3 bar, making it suitable for demanding wet areas.

6. Pack sizes for different project needs

Aqualock is available in 3 kg, 15 kg and 90 kg packs, which fit both small repairs and larger waterproofing jobs.

Advantages of Using Cementitious Waterproofing Coating

1. Compatibility with concrete and plaster substrates

As a cementitious waterproofing coating, Trubuild Aqualock integrates well with concrete and cement plaster surfaces, reducing the risk of debonding.

2. Balanced strength and flexibility

The acrylic modification gives a balance of toughness and flexibility, helping the waterproofing membrane coating handle thermal and structural movement better than plain cement coatings.

3. Suitable for water tanks and reservoirs

Because the system is non‑toxic and low in VOC, it can be used in potable water tanks, reservoirs and similar structures.

4. Ready‑to‑mix system for easy use

The product comes as a two‑part kit of powder and liquid that mixes into a smooth slurry with a mechanical mixer on site.

5. Ideal base for screed and tiling

After proper curing, Aqualock waterproofing membrane coating can be covered with a protective screed and tiles in areas such as bathrooms, balconies and swimming pools.

6. Support for long‑term leakage control

When applied in the recommended thickness and cured as directed, cementitious waterproofing coatings like Trubuild Aqualock help control seepage and damp patches for many years.

Applications

Trubuild Aqualock is suitable for a wide range of horizontal and vertical surfaces exposed to moisture or standing water. Typical applications include roofs, parking decks, bathrooms, toilets, kitchens, balconies and planters where leakage is a common concern. It is also used in swimming pools, water tanks, reservoirs and wet podium areas that remain submerged or face heavy splashing.

The waterproofing cementitious coating is suitable for concrete foundations, basement walls and lift pits, where it helps resist both seepage from surrounding soil and internal dampness. Trubuild Aqualock can be applied on any sound concrete, cement plaster or masonry surface that is at risk of moisture damage, provided correct surface preparation is followed.

How to use Trubuild Waterproofing Membrane Coating?

Step 1. Surface preparation

New concrete and masonry surfaces should be allowed to cure fully before application of Trubuild waterproofing membrane coating. The substrate must be clean and free from oil, grease, wax, loose particles, or any contaminant that may affect adhesion and spalled areas should be repaired with suitable polymer-modified mortar. Corners and junctions are best treated with coving using polymer-modified mortar so that the waterproofing film remains continuous.

The surface should reach a saturated surface dry (SSD) condition, meaning it is damp but without standing water or active leaks. Any visible cracks, holes or honeycombs should be opened, cleaned and filled with appropriate repair material before application. This preparation helps the Trubuild waterproofing membrane coating form a uniform and durable layer.

Step 2. Mixing

Use a mechanical mixer to slowly add the powder component of Trubuild Aqualock cementitious waterproofing solution into the liquid component in a clean container, mixing until a smooth, lump-free slurry is obtained. The mixed material should be allowed to stand for about 5 to 10 minutes so that entrapped air can escape. The slurry then needs to be used within the recommended pot life of about 40 to 45 minutes for best performance.

Step 3. Application

The Trubuild waterproofing membrane coating slurry can be applied using a brush or trowel in even coats. Water must not be added to the mix at any stage, as dilution affects the film build and performance. The recommended coverage is about 1.65 to 1.75 kg per square metre for two coats, depending on surface condition.

Allow the first coat to air cure for about 4 to 6 hours before applying the second coat of Aqualock in a perpendicular direction for better coverage. After the second coat, the system should air cure for around 5 to 6 hours and then be moist cured by light sprinkling or spraying of clean water for about 24 hours. The surface is then allowed to air cure for about 3 to 5 days before laying protective screed or tiles.

Step 4. Curing

For water tanks, swimming pools and spas, Trubuild Aqualock needs at least 7 days of curing before filling with water or conducting a ponding test. Tools and equipment can be cleaned with water immediately after use, while hardened material may need mechanical removal.

FAQ

What surfaces can Aqualock be applied on?

Trubuild Aqualock can be applied on sound concrete, cement plaster and masonry surfaces that face dampness or standing water. Common examples include roofs, bathrooms, balconies, basements, water tanks, swimming pools and foundations, where a cementitious waterproofing coating is needed for lasting protection

Is Aqualock flexible?

Trubuild Aqualock is an acrylic modified cementitious waterproofing coating that forms a flexible membrane over concrete and masonry surfaces. This flexible film helps bridge minor hairline cracks and surface movements. This supports long-term waterproofing performance in areas such as terraces, bathrooms and water tanks.

Can Aqualock be applied on damp surfaces?

Yes, Trubuild Aqualock waterproofing membrane coating can be applied on damp substrates prepared to a saturated surface dry condition, where the surface is moist but has no standing water or active leakage. This makes application practical in bathrooms, basements and water tanks where complete drying is difficult before waterproofing work.

How long does the waterproofing last?

Performance depends on correct surface preparation, recommended film thickness, proper curing, protection with screed or tiles and exposure conditions, so following application guidelines is important for long-term waterproofing.

Can Aqualock be used before tiling?

Trubuild Aqualock is designed as a cementitious waterproofing membrane that can be overlaid with protective screed and tile finishes after proper curing. Once the waterproofing membrane coating has cured as recommended and is protected with a suitable screed, tiles can be fixed over it in wet areas such as bathrooms, balconies and swimming pools.

Professional Sealants

Professional Sealants

Roof Waterproofing

Roof Waterproofing

Substructure Waterproofing

Substructure Waterproofing  Tiling and Grouting

Tiling and Grouting

Water Tanks and Other Areas

Water Tanks and Other Areas