Common Causes of Water Tank Leaks and How Waterproofing Prevents Them

Nov 28, 2025

Concrete water tanks play a key role in every Indian home. Be it a housing complex or commercial building, a small water tank leak can quickly turn into damp walls, fungal growth and high repair bills. This can happen with overhead and underground concrete tanks. This is why many homeowners and facility managers look for an effective water tank leakage solution that protects the structure and stored water. Modern concrete water tank waterproofing systems are made to handle Indian weather. They are also made for hard water and high usage. With the right combination of construction practices, regular checks and precautions like waterproofing, most concrete water tank leaks can be controlled or avoided in the first place.

Why Do Concrete Water Tanks Leak?

A concrete water tank may look strong from the outside. But its inner surface constantly faces water pressure. Over time, small weaknesses in the concrete or joints start to let water seep through. This often shows up as damp patches on the tank walls, peeling paint on nearby surfaces or water stains on ceilings below overhead tanks.

In India, temperature changes, poor-quality materials and rushed construction make concrete tanks more prone to cracking and seepage. Many tanks are also repaired temporarily. It fixes the visible leak but ignores the root cause.

Common Causes of Concrete Water Tank Leaks

1. Cracks in the Tank Walls or Floor

Hairline cracks start due to the shrinkage of concrete, structural movement or uneven support under the tank base. Even very thin cracks allow water to travel slowly through the concrete over time. If these cracks are not treated early, they widen and reach the outer surface. This leads to visible leakage, rusting of steel reinforcement and long-term damage to the tank.

2. Weak Construction Joints

Every concrete water tank has joints between walls and floor and sometimes between different casting stages. If these joints are not treated properly during construction, they act as leakage paths. Water pressure is highest at these meeting points. Any gap or poor bonding in the joint quickly leads to seepage lines along the tank corners and edges.

3. Poor-Quality Materials During Construction

Using low-grade cement, bad aggregates or a concrete mix with too much water creates a porous structure. Such concrete absorbs and passes water more easily. In many projects, additives and waterproofing compounds are ignored to save initial costs. This can lead to a higher chance of water tank leak issues within a few years of use.

4. Expansion and Contraction Due to Temperature Changes

Concrete expands in heat and contracts in cooler conditions. In Indian cities, overhead tanks face direct sun during the day and cooler temperatures at night. This leads to constant movement. This daily expansion and contraction cycle creates stress on the tank surface and joints. Over time, this stress shows up as visible cracks and micro-gaps where water can push through.

5. Plumbing Line Leakages

Inlet, outlet, overflow and washout pipes pass through the tank walls and floor. If these pipe openings are not sealed properly, water starts leaking around the pipe rather than through it. Leaks in plumbing lines can be tricky to spot. They often appear as damp rings around the pipe entry point and may be mistaken for simple condensation.

6. Lack of Proper Waterproofing

Bare concrete alone is rarely enough to act as a long-term water barrier. Without a planned, concrete water tank waterproofing system, seepage gradually increases with age and usage. Many tanks are put into use immediately after basic curing, with no protective coating, which leaves them more exposed to water penetration, chemical attack and micro-cracking.

7. Damage Due to Cleaning or Maintenance Tools

Rough cleaning using hard metal brushes, sharp tools or high-impact equipment can scratch or chip the inner surface of the tank. These marks weaken the waterproofing layer or expose the concrete below. Over time, repeated harsh cleaning cycles cause the coating to peel and create thin leak paths that spread across the tank floor and wall junctions.

How Does Waterproofing Prevent Concrete Water Tank Leaks?

Step 1: Creates a Seamless Leak-Proof Barrier

Modern concrete water tank waterproofing coatings form a continuous film over the inner surface of the tank. This film acts as a barrier that resists constant water pressure and blocks seepage. Because the barrier is seamless, there are no open joints on the coated surface. It also reduces the risk of localised water tank leak points.

Step 2: Seals Construction Joints and Micro-Cracks

Specialised waterproofing systems are made to bridge small cracks and cover construction joints. They penetrate surface pores and fill minor gaps that may not be visible to the naked eye. This sealing of micro-cracks and joints controls early seepage. It also extends the service life of new and repaired concrete tanks.

Step 3: Increases Tank Durability

By keeping water and dissolved salts away from the concrete and steel reinforcement, waterproofing reduces corrosion, surface erosion and chemical attack from stored water. This added protection means fewer structural repairs over the years, less risk of major cracks and a longer safe life for the concrete water tank.

Step 4: Prevent Health Risks

Leakage and seepage often lead to damp areas around the tank, which support algae, moss and fungal growth. In overhead tanks, even small cracks can allow dust and contaminants to enter through the damaged surface. A sound waterproofing layer supports better hygiene by maintaining a smooth, stable surface that is easier to clean and less likely to harbour growth.

Step 5: Reduce Repair Costs

Good waterproofing reduces the frequency of major structural repairs by addressing seepage at the surface level. This lowers the need for repeated patchwork and emergency tank shutdowns. For housing societies, institutions and industries, spending on a reliable concrete water tank waterproofing system often costs less over time than handling frequent leakage complaints.

Prevention Tips to Avoid Future Concrete Water Tank Leaks

To prevent future water tank leak, start by using the right concrete mix with the right water–cement ratio and clean aggregates. Adding waterproofing admixtures enhances strength and limits porosity. This helps tp build a solid foundation for lasting protection against a water tank leak.

Plan waterproofing during construction itself. Apply a suitable concrete water tank waterproofing system on inner walls, joints and pipe openings before the tank is filled. This step forms a durable base for long-term use.

Recoat every five to seven years to maintain protection. Clean the surface gently and repair cracks before applying a new layer. Avoid harsh tools when cleaning to prevent damaging the coating.

Finally, make sure to inspect the tank every six months. Spotting damp patches, rust spots or cracks early allows quick action with an effective water tank leakage solution, ensuring reliable performance for years.

Why Choose Astral Trubuild Aqualock for Concrete Water Tank Waterproofing?

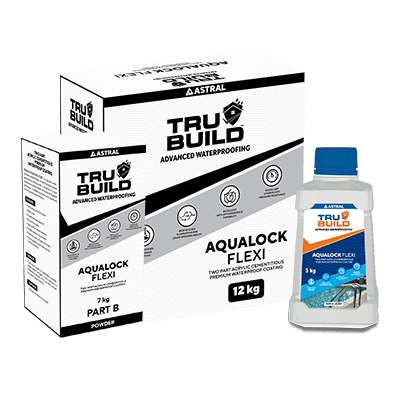

Our Trubuild Aqualock is a two-part waterproofing coating. It is especially esigned for concrete and masonry surfaces. When mixed and applied, it forms a seamless layer that creates an excellent water barrier. Here’s why it is the right choice for concrete water tank waterproofing:

- Safe for Drinking Water: It is completely non-toxic and free from harmful chemicals (VOC-free). This makes it safe for storing drinking water.

- Handles Water Pressure: It can withstand pressure up to 5 bar from inside the tank and 3 bar from outside. This is why it is ideal for overhead and underground water tanks.

- Flexible Protection: Water tanks expand and contract with temperature changes. Aqualock’s flexibility allows it to move with the concrete without cracking and it maintains a watertight seal.

- Strong Adhesion: It bonds firmly to concrete surfaces. It can even be applied on damp surfaces to ensure reliable, long-lasting protection.

- Seamless Coating: Applied as a liquid, Aqualock forms a continuous membrane with no joints or weak spots where leaks could develop.

For concrete water tanks, Aqualock provides the safe, durable and flexible waterproofing protection your water storage needs.

FAQ

Why do concrete water tanks crack?

Concrete water tanks crack due to shrinkage during curing, structural movement, uneven support, poor-quality concrete or temperature changes. Overloading of the tank base and lack of proper joint treatment can also create stress that turns into visible cracks.

What is the best solution for a leaking concrete water tank?

The best water tank leakage solution usually combines targeted crack repair with a suitable concrete water tank waterproofing system. Small cracks are treated and sealed, joints are strengthened and then a continuous waterproof coating is applied to the inner or outer surface as recommended by a specialist.

Can waterproofing stop concrete tank seepage permanently?

A high-quality waterproofing system applied by trained professionals can control concrete tank seepage for many years if maintenance and recoating cycles are followed. Long-term performance depends on product quality, correct application and regular inspection rather than a single one-time treatment.

Professional Sealants

Professional Sealants

Roof Waterproofing

Roof Waterproofing

Substructure Waterproofing

Substructure Waterproofing  Tiling and Grouting

Tiling and Grouting

Water Tanks and Other Areas

Water Tanks and Other Areas